《科学》:液体阳光 [美国媒体]

位于墨尔本郊区的莫纳什大学的化学家道格拉斯·麦克法兰说,澳大利亚古老而荒芜的陆地是新成长起来的事物的肥沃土壤:这里有大量的风车和太阳能电池板构成的森林。在澳大利亚,每平方米的阳光比其他任何地方都要多,而强劲的风则从其南部和西部沿海地区吹来。

Liquid sunshine

液体阳光

The ancient, arid landscapes of Australia are fertile ground for new growth, says Douglas MacFarlane, a chemist at Monash University in suburban Melbourne: vast forests of windmills and solar panels. More sunlight per square meter strikes the country than just about any other, and powerful winds buffet its south and west coasts. All told, Australia boasts a renewable energy potential of 25,000 gigawatts, one of the highest in the world and about four times the planet's installed electricity production capacity. Yet with a small population and few ways to store or export the energy, its renewable bounty is largely untapped.

位于墨尔本郊区的莫纳什大学的化学家道格拉斯·麦克法兰说,澳大利亚古老而荒芜的陆地是新成长起来的事物的肥沃土壤:这里有大量的风车和太阳能电池板构成的森林。在澳大利亚,每平方米的阳光比其他任何地方都要多,而强劲的风则从其南部和西部沿海地区吹来。总而言之,澳大利亚拥有25万千瓦的可再生能源潜力,这在全世界名列前茅,相当于全球装机容量的四倍。然而,由于人口稀少,储存或出口能源的方式很少,澳大利亚的可再生能源在很大程度上尚未得到开发。

That's where MacFarlane comes in. For the past 4 years, he has been working on a fuel cell that can convert renewable electricity into a carbon-free fuel: ammonia. Fuel cells typically use the energy stored in chemical bonds to make electricity; MacFarlane's operates in reverse. In his third-floor laboratory, he shows off one of the devices, about the size of a hockey puck and clad in stainless steel. Two plastic tubes on its backside feed it nitrogen gas and water, and a power cord supplies electricity. Through a third tube on its front, it silently exhales gaseous ammonia, all without the heat, pressure, and carbon emissions normally needed to make the chemical. “This is breathing nitrogen in and breathing ammonia out,” MacFarlane says, beaming like a proud father.

这就是麦克法兰进入的领域。在过去的4年里,他一直在研究一种燃料电池,它可以将可再生电力转化为无碳燃料:氨。燃料电池通常使用储存在化学键中的能量来发电;麦克法兰则进行了逆向操作。在三楼的实验室里,他展示了其中的一款设备,它的大小与冰球差不多,而且是不锈钢的。它的背面有两根里面注有氮气和水的塑料管,还有一根电源线用来供应电力。通过位于它前面的第三个管子,这个设备无声地呼出气体氨,所有这些都没有热量、压力和碳排放,而这三种条件通常是制造这种化学物质所需要的。麦克法兰说:“这是吸入氮气,呼出氨水。”他像一位骄傲的父亲一样微笑着。

Companies around the world already produce $60 billion worth of ammonia every year, primarily as fertilizer, and MacFarlane's gizmo may allow them to make it more efficiently and cleanly. But he has ambitions to do much more than help farmers. By converting renewable electricity into an energy-rich gas that can easily be cooled and squeezed into a liquid fuel, MacFarlane's fuel cell effectively bottles sunshine and wind, turning them into a commodity that can be shipped anywhere in the world and converted back into electricity or hydrogen gas to power fuel cell vehicles. The gas bubbling out of the fuel cell is colorless, but environmentally, MacFarlane says, ammonia is as green as can be. “Liquid ammonia is liquid energy,” he says. “It's the sustainable technology we need.”

世界各地的公司每年都要生产价值600亿美元的氨,主要是用作肥料,而麦克法兰的小发明可能会让这一过程更有效率、更清洁。但他的雄心远不止于帮助农民。通过将可再生电力转换为一种可以很容易地被冷却并压缩成液体燃料的高能气体,麦克法兰的燃料电池有效地将阳光和风装入瓶中,把它们变成一种商品,可以装运在世界任何地方,然后转换成电能或氢气来作为燃料电池汽车的动力。燃料电池里冒出来的气体是无色的,但麦克法兰说,在环境上而言,氨是绿色的。他说:“液态氨是液态的能源,它就是我们所需要的可持续发展技术”。

Ammonia—one nitrogen atom bonded to three hydrogen atoms—may not seem like an ideal fuel: The chemical, used in household cleaners, smells foul and is toxic. But its energy density by volume is nearly double that of liquid hydrogen—its primary competitor as a green alternative fuel—and it is easier to ship and distribute. “You can store it, ship it, burn it, and convert it back into hydrogen and nitrogen,” says Tim Hughes, an energy storage researcher with manufacturing giant Siemens in Oxford, U.K. “In many ways, it's ideal.”

氨——一个氮原子与三个氢原子结合而成的分子——看起来可能不像是一种理想的燃料:这种化学物质在家用作为清洁剂使用,气味难闻,而且有毒。但是它的能量密度是液态氢——它作为绿色替代燃料的主要竞争对手——的两倍,而且它更容易运输和配送。“你可以储存它,运送它,燃烧它,然后把它转换成氢和氮,”位于英国牛津的制造巨头西门子的能源存储研究员蒂姆·修斯说道,“在很多方面,它是完美的”。

Researchers around the globe are chasing the same vision of an “ammonia economy,” and Australia is positioning itself to lead it. “It's just beginning,” says Alan Finkel, Australia's chief scientist who is based in Canberra. Federal politicians have yet to offer any major legislation in support of renewable ammonia, Finkel says, perhaps understandable in a country long wedded to exporting coal and natural gas. But last year, the Australian Renewable Energy Agency declared that creating an export economy for renewables is one of its priorities. This year, the agency announced AU$20 million in initial funds to support renewable export technologies, including shipping ammonia.

全球各地的研究人员都在追求“氨经济”的前景,而澳大利亚正准备自己来引领它。驻堪培拉的澳大利亚首席科学家艾伦芬克尔说道:“这才刚刚开始”。芬克尔指出,联邦政府官员还没有提供任何支持可再生氨的主要立法,这在一个长期致力于煤炭和天然气出口的国家可能是可以理解的。但去年,澳大利亚可再生能源机构宣布,为可再生能源创造出口经济是它的首要任务之一。今年,该机构宣布投入2000万美元的初始资金,用于支持可再生能源出口技术,包括氨的运输技术。

In Australia's states, politicians see renewable ammonia as a potential source of local jobs and tax revenues, says Brett Cooper, chairman of Renewable Hydrogen, a renewable fuels consulting firm in Sydney. In Queensland, officials are discussing creating an ammonia export terminal in the port city of Gladstone, already a hub for shipping liquefied natural gas to Asia. In February, the state of South Australia awarded AU$12 million in grants and loans to a renewable ammonia project. And last year, an international consortium announced plans to build a US$10 billion combined wind and solar plant known as the Asian Renewable Energy Hub in Western Australia state. Although most of the project's 9000 megawatts of electricity would flow through an undersea cable to power millions of homes in Indonesia, some of that power could be used to generate ammonia for long-distance export. “Ammonia is the key enabler for exporting renewables,” says David Harris, research director for low-emissions technologies at Australia's Commonwealth Scientific and Industrial Research Organisation (CSIRO) Energy in Pullenvale. “It's the bridge to a whole new world.”

位于悉尼的可再生燃料咨询公司“生物制氢”的董事长布雷特·库珀指出,在澳大利亚的各州,政客们认为可再生氨是当地就业和税收收入的潜在来源。在昆士兰,官员们正在讨论在港口城市格莱斯顿建立一个氨出口终端,而该码头已经是向亚洲运送液化天然气的枢纽。今年2月,南澳大利亚州向一个可再生氨项目提供了1200万美元的赠款和贷款。去年,一个国际财团宣布计划在西澳大利亚州建立一个价值100亿美元的风能和太阳能发电厂,它将成为亚洲可再生能源的中心。尽管该项目的9000万千瓦电力将通过海底电缆传输到印尼为数百万家庭供电,但其中一些电力也可用于生产供长途出口的氨。位于普伦纳维尔的澳大利亚联邦科学与工业研究组织能源低排放技术研究主任大卫·哈里斯称:“氨是出口可再生能源的关键推动者,它是通往一个全新世界的桥梁”。

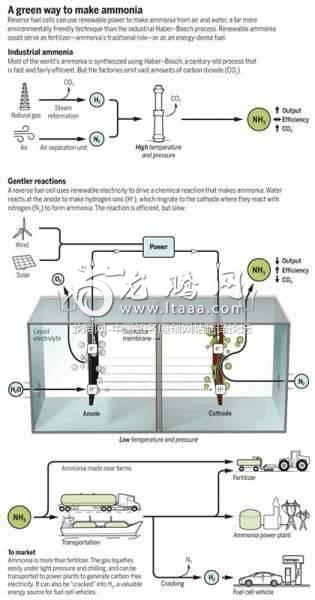

First, however, the evangelists for renewable ammonia will have to displace one of the modern world's biggest, dirtiest, and most time-honored industrial processes: something called Haber-Bosch.

然而,首先,可再生氨的传播者将不得不取代现代世界最大、最肮脏、最久享盛名的工业流程之一:一种被称为哈柏法的工艺。

THE AMMONIA FACTORY, a metallic metropolis of pipes and tanks, sits where the red rocks of Western Australia's Pilbara Desert meet the ocean. Owned by Yara, the world's biggest producer of ammonia, and completed in 2006, the plant is still gleaming. It is at the technological vanguard and is one of the largest ammonia plants in the world. Yet at its core are steel reactors that still use a century-old recipe for making ammonia.

“氨工厂”是一个由金属的管道和箱体构成的大都会,它坐落在西澳大利亚皮尔巴拉沙漠的红岩上。该工厂归世界上最大的氨生产企业雅苒国际公司所有,并于2006年完工,它目前仍在发出耀眼的光芒。这座作为技术先锋的工厂是世界上最大的氨工厂之一。然而,其核心是仍在使用的、具有百年历史的氨水配方的钢铁反应堆。

Until 1909, nitrogen-fixing bacteria made most of the ammonia on the planet. But that year, German scientist Fritz Haber found a reaction that, with the aid of iron catalysts, could split the tough chemical bond that holds together molecules of nitrogen, N2, and combine the atoms with hydrogen to make ammonia. The reaction takes brute force—up to 250 atmospheres of pressure in the tall, narrow steel reactors—a process first industrialized by German chemist Carl Bosch. The process is fairly efficient; about 60% of the energy put into the plant ends up being stored in the ammonia's bonds. Scaled up to factories the size of Yara's, the process can produce vast amounts of ammonia. Today, the facility makes and ships 850,000 metric tons of ammonia per year—more than double the weight of the Empire State Building.

直到1909年,固氮细菌仍然制造了地球上的大部分氨。但就在那一年,德国科学家弗里茨·哈伯发现了一种反应,即在铁催化剂的帮助下,可以分解将氮分子结合在一起的坚硬化学键,并将原子与氢结合成氨。这种反应需要蛮力——在高达250个大气压的高而窄的钢质反应堆中进行——这一过程首先由德国化学家卡尔·博世加以工业化。这个过程是相当有效的;输入工厂的大约60%的能量最终储存在了氨的化学键中。这个过程可以生产出大量的氨,并扩大到雅苒国际公司的大小工厂中。如今,该工厂每年生产和输送85万吨氨——比帝国大厦的重量还要高出一倍以上。

Australia's windy coasts offer a bounty of energy, which it might one day export as a carbon-free fuel.

澳大利亚多风的海岸提供了大量的能源,有一天它可能会作为无碳燃料出口。

Most is used as fertilizer. Plants crave nitrogen, used in building proteins and DNA, and ammonia delivers it in a biologically available form. Haber-Bosch reactors can churn out ammonia much faster than natural processes can, and in recent decades the technology has enabled farmers to feed the world's exploding population. It's estimated that at least half the nitrogen in the human body today comes from a synthetic ammonia plant.

大多数的氨被用作肥料。植物渴望氮,它被用于制造蛋白质和DNA的过程,而氨则以生物可利用的形式输送它。哈伯法反应堆可以以比自然过程更快的速度制造氨,而且近几十年来,这种技术使农民能够养活世界上不断膨胀的人口。据估计,今天人体中至少有一半的氮来自合成氨装置。

Haber-Bosch led to the Green Revolution, but the process is anything but green. It requires a source of hydrogen gas (H2), which is stripped away from natural gas or coal in a reaction using pressurized, super-heated steam. Carbon dioxide (CO2) is left behind, accounting for about half the emissions from the overall process. The second feedstock, N2, is easily separated from air, which is 78% nitrogen. But generating the pressure needed to meld hydrogen and nitrogen in the reactors consumes more fossil fuels, which means more CO2. The emissions add up: Ammonia production consumes about 2% of the world's energy and generates 1% of its CO2.

哈伯法引领了绿色革命,但这个过程绝对不是环保的。它需要氢气,而这种气体是通过加压的、过热的蒸汽,从天然气或煤炭中剥离出来。二氧化碳被留了下来,它约占整个过程排放物的一半。第二种原料——氮气——则很容易从空气中分离出来,空气中含有78%的氮气。但是,在反应堆中产生氢气和氮气所需要的压力会消耗更多的化石燃料,这意味着排放更多的二氧化碳。这些排放加起来:氨生产消耗了世界上2%的能源,产生了1%的二氧化碳。

Yara is taking a first step toward greening that process with a pilot plant, set to open in 2019, that will sit next to the existing Pilbara factory. Instead of relying on natural gas to make H2, the new add-on will feed power from a 2.5-megawatt solar array into a bank of electrolyzers, which split water into H2 and O2. The facility will still rely on the Haber-Bosch reaction to combine the hydrogen with nitrogen to make ammonia. But the solar-powered hydrogen source cuts total CO2 emissions from the process roughly in half.

雅拉正朝着绿色环保的方向迈出第一步,它的一座实验工厂将于2019年投产,该工厂将坐落在现有的皮尔巴拉工厂旁边。这个新的工厂不再依靠天然气来制造氢气,而是将一个2.5兆瓦的太阳能阵列产生的电力输送到一个电解液库中,电解液将水分解成氢气和氧气。该设施仍将依赖于哈伯法的反应,将氢与氮结合起来制造氨。但是太阳能制造的氢气在这个过程中减少了大约一半的二氧化碳排放量。

Other projects are following suit. The state of South Australia announced plans in February to build a AU$180 million ammonia plant, again relying on electrolyzers powered by renewable energy. Slated to open in 2020, the plant would be a regional source of fertilizer and liquid ammonia, which can be burned in a turbine or run through a fuel cell to make electricity. The supply of liquid energy will help stabilize the grid in South Australia, which suffered a debilitating blackout in 2016.

其他项目也紧随其后。今年2月,南澳大利亚州宣布了一项计划,将建造一座价值1.8亿美元的氨水厂,该工厂再次依靠可再生能源发电。该工厂计划于2020年开放,它将成为一个区域性的肥料和液态氨的来源,后者可以在涡轮机中燃烧,或者通过燃料电池发电。液态能源的供应将有助于稳定南澳大利亚的电网,该地区在2016年遭受了一次严重的停电事故。

Ammonia made this way should attract buyers in places such as the European Union and California, which have created incentives to buy greener fuels. And as the market grows, so will the distribution routes for importing ammonia and the technologies for using it, Harris says. By then, fuel cells like MacFarlane's could be ready to displace Haber-Bosch itself—and the half-green approach to ammonia production could become fully green.

以这种方式生产的氨应该会吸引到欧盟和加州等地的买家,这些地方已经出现了购买绿色燃料的动机。哈里斯说,随着市场的增长,进口氨的分销渠道和使用氨的技术也会越来越多。到那时,像麦克法兰这样的燃料电池就可以取代哈伯法本身了——而半绿色的氨生产方式可能会变成完全绿色的。

INSTEAD OF APPLYING fearsome heat and pressure, reverse fuel cells make ammonia by deftly wrangling ions and electrons. As in a battery being charged, charged ions flow between two electrodes supplied with electricity. The anode, covered with a catalyst, splits water molecules into O2, hydrogen ions, and electrons. The protons flow through an electrolyte and a proton-permeable membrane to the cathode, while the electrons make the journey through a wire. At the cathode, catalysts split N2 molecules and prompt the hydrogen ions and electrons to react with nitrogen and make ammonia.

与施加可怕的热量和压力相反,反向燃料电池通过巧妙地纠缠离子和电子来制造氨。就像在电池充电时,带电离子在两个电极之间流动。阳极被催化剂覆盖,将水分子分解成氧气、氢离子和电子。质子通过电解液和质子渗透膜进入阴极,而电子则通过导线开始它的旅程。在阴极中,催化剂分裂氮分子并促使氢离子和电子与氮发生反应,从而生成氨。

At present, the yields are modest. At room temperature and pressure, the fuel cell reactions generally have efficiencies of between 1% and 15%, and the throughput is a trickle. But MacFarlane has found a way to boost efficiencies by changing the electrolyte. In the water-based electrolyte that many groups use, water molecules sometimes react with electrons at the cathode, stealing electrons that would otherwise go into making ammonia. “We're constantly fighting having the electrons going into hydrogen,” MacFarlane says.

目前,它的效益仍是适度的。在室温和常压下,燃料电池的一般反应效率在1%到15%之间,但产量仍然很小。不过麦克法兰已经找到了一种通过改变电解液来提高效率的方法。在许多群组使用的水基电解质中,水分子有时会在阴极处与电子发生反应,窃取走电子,如果不出现这种情况,就会产生氨。“我们一直在努力让电子进入氢当中,”麦克法兰说。

To minimize that competition, he opted for what's called an ionic liquid electrolyte. That approach allows more N2 and less water to sit near the catalysts on the cathode, boosting the ammonia production. As a result, the efficiency of the fuel cell skyrocketed from below 15% to 60%, he and his colleagues reported last year in Energy & Environmental Science. The result has since improved to 70%, MacFarlane says—but with a tradeoff. The ionic liquid in his fuel cell is goopy, 10 times more viscous than water. Protons have to slog their way to the cathode, slowing the rate of ammonia production. “That hurts us,” MacFarlane says.

为了减少这种竞争,他选择了所谓的离子液体电解质。这种方法允许更多的氮和更少的水在阴极的催化剂附近,从而提高氨的产量。他和他的同事去年在《能源与环境科学》杂志上发文指出,通过这种方法,燃料电池的效率从15%飙升到了60%。麦克法兰指出,结果已经提高到了70%,但这只是一种折衷的办法。他的燃料电池里的离子液体比水的粘性大了10倍。质子必须缓慢地进入阴极,从而减慢了氨的生产速度。

To speed things up, MacFarlane and his colleagues are toying with their ionic liquids. In a study published in April in ACS Energy Letters, they report devising one rich in fluorine, which helps protons pass more easily and speeds ammonia production by a factor of 10. But the production rate still needs to rise by orders of magnitude before his cells can meet targets, set for the field by the U.S. Department of Energy (DOE), that would begin to challenge Haber-Bosch.

为了加快速度,麦克法兰和他的同事们正在调整他们的离子液体。在今年4月发表在《美国化学学会能源快报》上的一项研究中,他们报告称设计出了一种富含氟的物质,可以帮助质子更容易地通过,从而使氨的生产速度提高10倍。但是,在他的电池能够达到美国能源部设定的指标——从而开始挑战哈柏法——之前,其生产速率仍然需要增加一个数量级。

Next to Monash University, Sarb Giddey and his colleagues at the Clayton offices of CSIRO Energy are making ammonia with their “membrane reactor.” It relies on high temperatures and modest pressures—far less than those in a Haber-Bosch reactor—that, compared to MacFarlane's cell, boost throughput while sacrificing efficiency. The reactor designs call for a pair of concentric long metallic tubes, heated to 450°C. Into the narrow gap between the tubes flows H2, which could be made by a solar- or wind-powered electrolyzer. Catalysts lining the gap split the H2 molecules into individual hydrogen atoms, which modest pressures then force through the atomic lattice of the inner tube wall to its hollow core, where piped-in N2 molecules await. A catalytically active metal such as palladium lines the inner surface, splitting the N2 and coaxing the hydrogen and nitrogen to combine into ammonia—much faster than in MacFarlane's cell. So far only a small fraction of the input H2 reacts in any given pass—another knock to the reactor's efficiency.

坐落于莫纳什大学旁边的澳大利亚联邦科学与工业研究组织的克莱顿办公室的Sarb Giddey和他的同事们正在用他们的“膜反应器”制造氨。“它依赖于高温和适度的压力——远低于哈柏法的反应堆——与麦克法兰的电池相比,它能提高吞吐量,但同时也牺牲了效率。”反应堆设计中需要一对同心的长金属管,并被加热到450度。在管道之间的狭窄缝隙中,氢气可以由太阳能或风力的电解槽进行制造。在缝隙中,催化剂将氢分子分解成一个个的氢原子,然后凭借适度的压力迫使其通过内管壁的原子晶格进入空心内核,而插入的氮分子就在那里等待着。诸如钯这样的催化活性的金属则线性排列于内部表面,分解氮分子,诱使氢原子和氮原子结合成氨——这比麦克法兰的电池要快得多。到目前为止,在任何给定的通道中,只有一小部分的输入氢气会发生反应——这又一次降低了反应堆的效率。

Other approaches are in the works. At the Colorado School of Mines in Golden, researchers led by Ryan O'Hayre are developing button-size reverse fuel cells. Made from ceramics to withstand high operating temperatures, the cell can synthesize ammonia at record rates—about 500 times faster than MacFarlane's fuel cell. Like Giddey's membrane reactors, the ceramic fuel cells sacrifice some efficiency for output. Even so, O'Hayre says, they still need to improve production rates by another factor of 70 to meet the DOE targets. “We have a lot of ideas,” O'Hayre says.

其他的方法正在研究当中。在戈尔登的科罗拉多矿业学校,由瑞安奥海雷领导的研究人员正在开发纽扣大小的反向燃料电池。该电池由陶瓷制成,可以承受较高的工作温度,它可以以创纪录的速度合成氨——比麦克法兰的燃料电池快500倍。就像Giddey的膜反应器一样,陶瓷燃料电池为了输出牺牲了一些效率。即便如此,奥海雷宣称,他们仍然需要将生产效率提高到70倍,才能达到美国能源部的目标。奥海雷说:“我们有很多想法”。

Whether any of those approaches will wind up being both efficient and fast is still unknown. “The community is still trying to figure out what direction to go,” says Lauren Greenlee, a chemical engineer at the University of Arkansas in Fayetteville. Grigorii Soloveichik, a manager in Washington, D.C., for the DOE's Advanced Research Projects Agency-Energy program on making renewable fuels, agrees. “To make [green] ammonia is not hard,” he says. “Making it economically on a large scale is hard.”

这些方法是否最终会变得高效和快速仍然是未知的。位于费耶特维尔的阿肯色大学的化学工程师劳伦格林利指出:“业界仍在试图弄清楚该走哪条路。”华盛顿特区的一名名叫Grigorii Soloveichik、负责能源部的制造可再生燃料的高级研究项目的主管人员同意这一观点:“制造绿色氨并不难,但在经济上进行大规模生产是困难的”。

HOWEVER DISTANT, the prospect of Asia-bound tankers, full of green Australian ammonia, raises the next question. “Once you get ammonia to market, how do you get the energy out of it?” asks Michael Dolan, a chemist at CSIRO Energy in Brisbane.

不管多么遥远,满载着绿色澳大利亚氨的亚洲油轮的前景仍然提出了下一个问题。位于布里斯班的CSIRO能源的化学家迈克尔·多兰问道:“一旦你把氨推向市场,你怎么能从它中获得能量呢?”

The simplest option, Dolan says, is to use the green ammonia as fertilizer, like today's ammonia but without the carbon penalty. Beyond that, ammonia could be converted into electricity in a power plant customized to burn ammonia, or in a traditional fuel cell, as the South Australia plant plans to do. But currently, ammonia's highest value is as a rich source of hydrogen, used to power fuel cell vehicles. Whereas ammonia fertilizer sells for about $750 a ton, hydrogen for fuel cell vehicles can go for more than 10 times that amount.

多兰说,最简单的方法是把绿色氨作为肥料使用,就像今天的氨一样,但它没有碳排放。除此之外,氨可以被改造用于发电厂,用于燃烧氨,或者使用在传统的燃料电池中,就像南澳大利亚工厂计划做的那样。但目前,氨的最高价值却是作为一种富含氢的来源,用于为燃料电池汽车提供动力。尽管氨肥的售价约为每吨750美元,但燃料电池汽车的氢燃料的价格可能是这一数字的10倍以上。

In the United States, fuel cell cars seem all but dead, vanquished by battery-powered vehicles. But Japan is still backing fuel cells heavily. The country has spent more than US$12 billion on hydrogen technology as part of its strategy to reduce fossil fuel imports and meet its commitment to reduce CO2 emissions under the Paris climate accord. Today the country has only about 2500 fuel cell vehicles on the road. But by 2030 Japanese officials expect 800,000. And the nation is eyeing ammonia as a way to fuel them.

在美国,燃料电池汽车似乎已经走投无路,正在被电池驱动的汽车所击败。但日本仍在大力支持燃料电池。作为减少化石燃料进口的战略的一部分,中国已经花费了120多亿美元用于氢技术,并履行了在巴黎气候协议下减少二氧化碳排放的承诺。今天,这个国家只有大约2500辆燃料电池汽车行驶在路上。但到2030年,日本官员预计这一数字将达到80万。这个国家正在把氨作为一种燃料来为它们提供燃料。

Converting hydrogen into ammonia only to convert it back again might seem strange. But hydrogen is hard to ship: It has to be liquefied by chilling it to temperatures below ?253°C, using up a third of its energy content. Ammonia, by contrast, liquefies at ?10°C under a bit of pressure. The energy penalty of converting the hydrogen to ammonia and back is roughly the same as chilling hydrogen, Dolan says—and because far more infrastructure already exists for handling and transporting ammonia, he says, ammonia is the safer bet.

将氢转化为氨,却只是为了将它再转化回来,这可能看起来很奇怪。但是氢很难运输:它必须通过冷却到低于253摄氏度的温度来液化,这将消耗掉它三分之一的能量。相比之下,氨却可以在零下10摄氏度、略微增压的条件下被液化。他指出,将氢转化为氨和回流的能量损失与冷却氢大致相同,而且由于更多的基础设施已经用于处理和运输氨,因此,氨是一种更安全的选择。

That last step—stripping hydrogen off ammonia molecules—is what Dolan and his colleagues are working on. In a cavernous metal warehouse on the CSIRO campus that has long been used to study coal combustion, two of Dolan's colleagues are assembling a 2-meter-tall reactor that is dwarfed by a nearby coal reactor. When switched on, the reactor will “crack” ammonia into its two constituents: H2, to be gathered up for sale, and N2, to waft back into the air.

最后一步——将氢从氨分子中分离出来——是多兰和他的同事们正在研究的课题。在澳大利亚联邦科学与工业研究组织所在地的一个长期以来一直被用来研究煤炭燃烧的巨大金属仓库里,多兰的两个同事正在组装一个2米高的反应堆,与附近的一个煤反应堆相比,这个反应堆显得微不足道。当接通电源时,反应器将会把氨“裂解”为两个组成部分:氢气——它将被收集起来出售——和氮气——它将返回到空气中。

That reactor is basically a larger version of Giddey's membrane reactor, operating in reverse. Only here, gaseous ammonia is piped into the space between two concentric metal tubes. Heat, pressure, and metal catalysts break apart ammonia molecules and push hydrogen atoms toward the tube's hollow core, where they combine to make H2 that's sucked out and stored.

这个反应堆基本上是Giddey的膜反应器的一个加大版,并且进行了反向操作。只有在这里,气体氨被输送到两个同心金属管之间的空隙中。热度、压力和金属催化剂分解了氨分子,将氢原子推向管子的空心核心,在那里它们结合形成氢气,然后被吸出并储存起来。

Ultimately, Dolan says, the reactor will produce 15 kilograms per day of 99.9999% pure hydrogen, enough to power a few fuel cell cars. Next month, he plans to demonstrate the reactor to automakers, using it to fill tanks in a Toyota Mirai and Hyundai Nexo, two fuel cell cars. He says his team is in late-stage discussions with a company to build a commercial pilot plant around the technology. “This is a very important piece of the jigsaw puzzle,” Cooper says.

多兰说,反应堆最终每天将产生出15公斤的纯度达到99.9999%的氢气,足够为好几辆燃料电池汽车提供动力。下个月,他计划向汽车制造商展示这个反应堆,用它来填充丰田Mirai和现代Nexo两款燃料电池汽车的油箱。他说,他的团队正在与一家公司进行后期谈判,以围绕这项技术建立一个商业试点工厂。库珀指出:“这是拼图游戏中非常重要的一块”。

Beyond 2030, Japan will likely import between $10 billion and $20 billion of hydrogen each year, according to a renewable energy roadmap recently published by Japan's Ministry of Economy, Trade and Industry. Japan, Singapore, and South Korea have all begun discussions with Australian officials about setting up ports for importing renewably produced hydrogen or ammonia. “How it all comes together economically, I don't know,” Harris says. “But it looks like there's enough interest to get this industry started.”

日本经济产业省最近发布的一份可再生能源路线图显示,到2030年以后,日本每年可能会进口100到200亿美元的氢气。日本、新加坡和韩国都已开始与澳大利亚官员讨论建立港口,以进口可再生的氢或氨的事宜。哈里斯说:“我不知道这一切是如何在经济上走到一起的。但似乎人们有足够的兴趣让这个行业开始起步”。

Cooper knows how he wants it to end. Over coffee on a rainy morning in Sydney, he describes his futuristic vision for renewable ammonia. When he squints, he can see, maybe 30 years down the road, Australia's coast dotted with supertankers, docked at offshore rigs. But they wouldn't be filling up with oil. Seafloor powerlines would carry renewable electricity to the rigs from wind and solar farms on shore. On board, one device would use the electricity to desalinate seawater and pass the fresh water to electrolyzers to produce hydrogen. Another device would filter nitrogen from the sky. Reverse fuel cells would knit the two together into ammonia for loading on the tankers—a bounty of energy from the sun, air, and sea.

库珀知道他想要怎样结束。在悉尼一个下雨的早晨,他在喝咖啡时,描述了他对可再生氨的未来愿景。当他眯着眼的时候,他可以预见到,也许在未来的30年里,澳大利亚的海岸上停泊着超级油轮,它们停靠在海上的钻井平台上。但它们的内部不会被石油填满。海底的电力线将把可再生电力输送到岸上的风力和太阳能发电厂。在船上,一种设备将利用电力来淡化海水,并将淡水输送到电解液中以产生氢气。另一种装置可以从天空中过滤氮气。反向燃料电池会将两者结合成氨,再装入油轮——这是来自太阳、空气和海洋的巨额能量。

It's the dream that nuclear fusion never reached, he says: inexhaustible carbon-free power, only this time from ammonia. “It can never run out, and there is no carbon in the system.”

他说,这是核聚变从未达到的梦想:取之不尽的无碳能源,只不过这一次是来自氨。“它永远不会耗尽,其系统中也没有碳”。

版权声明

我们致力于传递世界各地老百姓最真实、最直接、最详尽的对中国的看法

【版权与免责声明】如发现内容存在版权问题,烦请提供相关信息发邮件,

我们将及时沟通与处理。本站内容除非来源注明五毛网,否则均为网友转载,涉及言论、版权与本站无关。

本文仅代表作者观点,不代表本站立场。

本文来自网络,如有侵权及时联系本网站。

阅读:

图文文章RECOMMEND

热门文章HOT NEWS

-

1

Why do most people who have a positive view of China have been to ...

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

推荐文章HOT NEWS

-

1

Why do most people who have a positive view of China have been to ...

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10