【经济学人】航空旅行:微型机器人将从内部检修喷气式发动机 [英国媒体]

如果您在坐飞机时阅读这篇文章,并且容易感到紧张,请不要惊慌,这架飞机的喷气式发动机的内部温度可能超过了发动机材料的熔点。发动机不会因此被熔化,这是现代工程学的壮举。发动机是坚硬合金与先进生产工艺的结晶,例如三维打印使零部件拥有微小的冷气循环通道。零部件所处的最高温度在1300℃以上,特殊的耐热陶瓷涂层为其提供额外保护。

Air travel

航空旅行

Tiny robots will inspect and fix jet engines from the inside

微型机器人将从内部检修喷气式发动机

Robotic mechanics can go anywhere

机器人维修工随处可去

IF YOU are reading this while sitting in an aircraft and are of a nervous disposition, do not be alarmed, but the temperature inside the jet engines keeping you aloft probably exceeds the melting point of the materials that those engines are made from. That they do not consequently turn into a molten mess is a feat of modern engineering. It involves a combination of tough alloys and advanced production techniques, such as 3D printing, which allow components to be made with tiny channels through which cooling air circulates. Parts exposed to the most extreme temperatures, which can reach more than 1,300°C, are given additional protection with a coating of special heat-resisting ceramics.

如果您在坐飞机时阅读这篇文章,并且容易感到紧张,请不要惊慌,这架飞机的喷气式发动机的内部温度可能超过了发动机材料的熔点。发动机不会因此被熔化,这是现代工程学的壮举。发动机是坚硬合金与先进生产工艺的结晶,例如三维打印使零部件拥有微小的冷气循环通道。零部件所处的最高温度在1300℃以上,特殊的耐热陶瓷涂层为其提供额外保护。

New jet engines are designed to run hot because that results in a more efficient combustion, which lowers fuel consumption and cuts emissions. Hot engines, though, need nurturing. Nowadays the three big aircraft-engine makers, General Electric (GE), Rolls-Royce and Pratt & Whitney, usually include servicing as part of their sales, and many jet engines are leased on a “power-by-the-hour” contract. This means regular check-ups and maintenance are in the interests of airlines and producers alike. The difficult bit is inspecting an engine without dismantling it. That requires taking the aircraft to which the engine is attached out of service. And, with a power-by-the-hour contract, when a plane disappears into the workshop, it is not just the airline that loses money, but the engine maker, too. The hunt is therefore on for faster and more efficient ways to keep engines in tip-top condition.

新型喷气式发动机旨在高温环境下工作,因为这样能提高燃烧效率,从而减少燃料消耗和废气排放。但是,高温下工作的发动机需要维护。当今三大飞机发动机制造商通用电气、劳斯莱斯、惠普通常将维护作为销售的一部分,许多喷气式发动机依据“按小时包修合同” 出租,这意味着日常检修与维护是航空公司和制造商的共同利益。难点是在不拆卸的情况下检修发动机,这需要发动机所在的飞机停止工作。而且根据“按小时包修合同”,当飞机在工厂接受检修时,航空公司和制造商都会赔钱。因此,他们寻求更快、更高效的方式保持发动机处在巅峰状态。

Don Lipkin, a chief scientist at GE Global Research in Niskayuna, New York, and his colleagues Todd Danko and Kori Macdonald, think they have come up with one. They are developing tiny robots which can venture inside an engine to inspect its innards and carry out any necessary repairs. Eventually, these robots may be able to work while a plane is waiting at a gate between flights.

丹•利普金是位于纽约尼什卡纳的“通用电气全球研究中心”的首席科学家,他与同事托德•丹科、克里•唐纳德认为想出了一种办法。他们研发的微型机器人敢进入发动机内部检查零部件,并进行必要的修理。最终,当飞机处于航班间隙在门口等待时,这些机器人就可以工作了。

Send in the microbots

Dr Lipkin’s robots are being tested in a laboratory, but he hopes to have them ready to go inside operating aircraft by the end of the year. To start with, they will conduct inspections. Later, once techniques are perfected, they will begin making repairs. Such robots will also be used to inspect and repair GE’s gas turbines. These are jet engines used in power plants to generate electricity, rather than as propulsion devices. But they, too, would benefit from reduced downtime for maintenance.

派遣微型机器人

利普金博士的机器人处在实验室测试阶段,但他期待年底让机器人进入工作中的飞机内部。最初它们会进行检查,未来一旦技术成熟将进行维修。通用电气公司还将利用这种机器人检修燃气轮机,这些喷气式发动机被电厂用于发电,而不是作为推进装置,但停机维护时间减少也能使其受益。

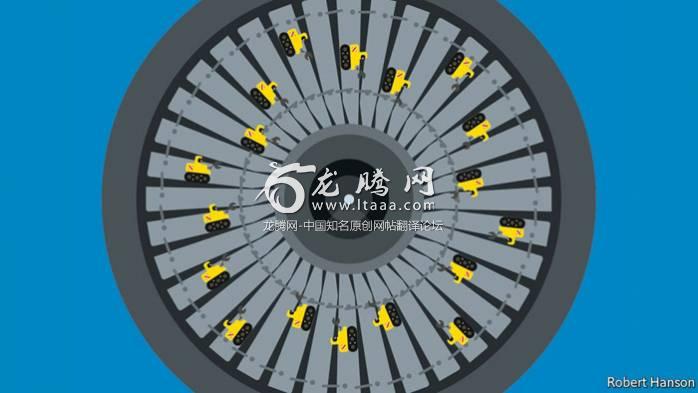

Inspecting the fan blades that draw air into the front of an engine is reasonably straightforward, because those blades are large and visible. But things get harder the deeper you go. Following the fan are a series of closely packed blades that compress some of the air before it arrives at the combustion chamber. When the compressed air reaches that chamber, and is mixed with fuel and ignited, the resulting hot gases then blast out of the rear, providing part of the thrust. The gases pass through a series of stubby turbine blades near the back of the engine. These, via shafts, turn the fan and the compressor, and thus keep the whole arrangement running.

将空气吸入发动机前部的扇叶检查起来非常容易,因为它们体积大且显眼。但越往深处难度越大,风扇后面是许多密集的扇叶,负责在空气进入燃烧室前压缩一部分空气。空气进入燃烧室,与燃料混合并点火,产生的热气从尾部喷出,提供一部分推力。气体经过发动机尾部许多短粗的涡轮叶片,通过传动轴推动风扇和压缩机转动,进而维持整个装置运行。

In a working engine, all of these components are so tightly packed together that sometimes the only way to peek inside is by inserting an endoscope (a camera on a flexible tube) through a hole in the engine’s casing. But the view is limited. The researchers’ robots, however, are small enough to navigate their way around all the various blades, photographing everything they see and relaying the pictures wirelessly to technicians. Then, once the pictures have been analysed, the robot itself can often effect a repair.

在运行的发动机内,所有部件排列得相当紧凑,有时检查内部的唯一方式是从发动机罩上的小孔插入内窥镜(安装在挠性管上的摄像头),不过视野有限。他们研发的机器人小到可以绕过各种扇叶,拍摄所见的一切,再将照片无线传输给技术人员。一旦照片经过分析,机器人通常能够进行维修。

The team’s robots come in several varieties. One is about the size of a small envelope and is flexible. It runs along a sort of rack-and-pinion track that is inserted into the back of the engine. The track is made from a long strip of plastic which, with a twisting action, can be flicked between the blades. The robot is attached to the track and employs a toothed drive-mechanism which connects to a series of holes in the plastic strip and permits the device to propel itself along. Once it has arrived at its destination, it expands so that it is gripped between a pair of blades. The track is withdrawn and the robot hitches a ride on the blades as these are rotated manually by technicians. That way it can photograph internal surfaces adjacent to the blades as it passes. Once its job is done, it can be pulled out on a cord.

该团队研发出多种机器人。一种是小信封尺寸的弹性机器人,沿着发动机尾部嵌入的齿轮齿条轨道移动。轨道由长条塑料制成,具有扭转作用,能在扇叶之间快速移动。连接在轨道上的机器人利用齿形传动机构,该机构与塑料条上的小孔相连,推动轨道向前移动。当轨道到达目的地时,自身展开,夹在两片扇叶之间。轨道被撤走,技术人员用手转动扇叶使机器人附在上面。这样,机器人沿途拍摄扇叶周围的内表面。当机器人完成任务时,可用绳子将其拉出来。

Another type of robot, a few centimetres square, crawls inside an engine on caterpillar tracks. A third version uses magnetic wheels. These let it grip surfaces made with specialised steels in the cold front section of ground-based gas turbines, and thus work upside down if necessary. All the robots are driven by a human operator using a tablet computer. To repair things, the machines are fitted with tiny arms that reach out and inject ceramic coatings from a cartridge of material to fill in any damaged areas. The robots can also carry small grinding tools, to smooth down ragged surfaces.

还有一种四米见方的机器人,依靠履带爬入发动机内部。第三种机器人采用磁力轮,吸附在地面燃气轮机前部冷区域的特质钢板上,从而在必要时倒立工作。技术人员通过平板电脑操控所有机器人。当需要修理时,机器人伸出微型机械臂,将材料盒内的陶瓷涂层注入受损区域。它们还能携带小型磨具,平整粗糙表面。

Such repairs may not be as permanent as those during a full rebuild, but they are good enough to extend the time an engine can operate between major overhauls. Moreover, data collected by the robots would be used by GE to update the engine’s “digital twin”. These twins are virtual replicas, held on a computer, and contain the latest operating data sent via satellites from sensors mounted inside engines. The twins serve as test beds for spotting problems before they get serious. This means preventive maintenance can be carried out and unscheduled visits to the workshop avoided.

这种修理效果可能不如大修那样持久,但足已延长发动机在大修间隔的工作时间。另外,“通用电气”可利用机器人收集的数据更新发动机的“数字双胞胎”。这些双胞胎是在计算机上运行的虚拟镜像,包含发动机内的传感器通过卫星传送的实时运行数据。“数字双胞胎”作为试验台,在问题严重之前发现问题。这意味着预防性维修的实现,避免非计划性维修。

Robots will allow much finer monitoring of an engine’s wear and tear. That varies, according to how aircraft are used—even by particular pilots, some of whom push aircraft engines harder than others do—and where in the world a plane most often operates. Airborne particles, particularly in polluted regions, can block the tiny cooling channels that help stop an engine melting. Wind-blown sand grains in places such as the Middle East subject blades to increased abrasion. Jet engines are already remarkably reliable, with the need for an in-flight shutdown now in the order of once in 20,000 hours of operation, which means a pilot may never experience a failure in his entire career. Tiny robots will make them more so.

机器人能更精细的监控发动机的磨损状况。磨损差异取决于飞行员如何驾驶飞机,有些飞行员使用发动机比较猛,还取决于飞机在世界哪个地区飞行最频繁。尤其在受污染区,防止发动机熔化的微小冷却通道能被悬浮颗粒堵塞。中东等地区的风沙会加重扇叶磨损。喷气式发动机已经非常可靠,如今每飞行20000小时约有一次需要空中停车,这意味着飞行员在整个职业生涯可能永远不会遇到故障,有了微型机器人更为如此。

版权声明

我们致力于传递世界各地老百姓最真实、最直接、最详尽的对中国的看法

【版权与免责声明】如发现内容存在版权问题,烦请提供相关信息发邮件,

我们将及时沟通与处理。本站内容除非来源注明五毛网,否则均为网友转载,涉及言论、版权与本站无关。

本文仅代表作者观点,不代表本站立场。

本文来自网络,如有侵权及时联系本网站。

图文文章RECOMMEND

热门文章HOT NEWS

-

1

最近,新冠肺炎疫情在日本有扩大的趋势,有专家呼吁日本应当举国行动起来,共...

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

推荐文章HOT NEWS

-

1

最近,新冠肺炎疫情在日本有扩大的趋势,有专家呼吁日本应当举国行动起来,共...

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10